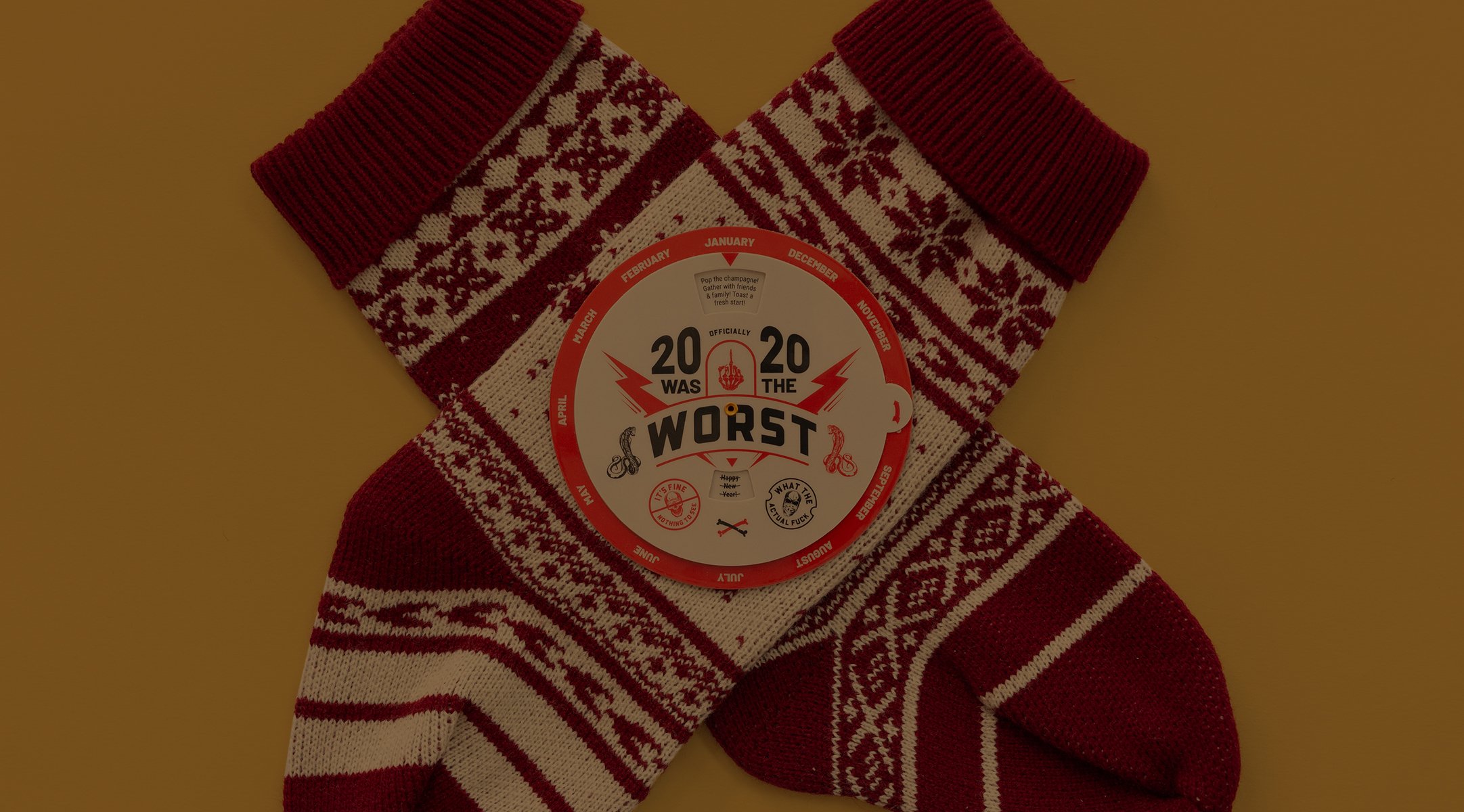

2020 was the Worst Volvelle

Paper Engineering Project | 2020

-

Dieline Development | Printing Mechanicals

-

Conceptual Strategy | Design and Layout | Packaging

I had this idea to do a funny 2020 volvelle as a stocking stuffer gift. I partnered with my copywriter to come up with the progression of each month’s new surprises and realities we all faced in 2020. It was a way to bring humor and community to something we were all going through and, quite frankly, just needed to find a way to laugh about it. The volvelle was diecut on a Heidelberg letterpress machine, laminated and assembled using a brass eyelet. The final size of the volvelle was 5”. The biggest lesson I learned from this volvelle was the eyelet — the ended up being too tight. After the project was complete, I ended up purchasing my own Stimpson 405 eyelet press for future volvelles, allowing me to control how smooth the volvelle spun and lower my production costs.